Silicone Embossing Machine Is Popular In Cloting Industry

December 19, 2023

The concave and convex embossing process is one of the important methods for surface art processing of clothing, luggage and accessories fabric products, and it has attracted more and more people's attention.

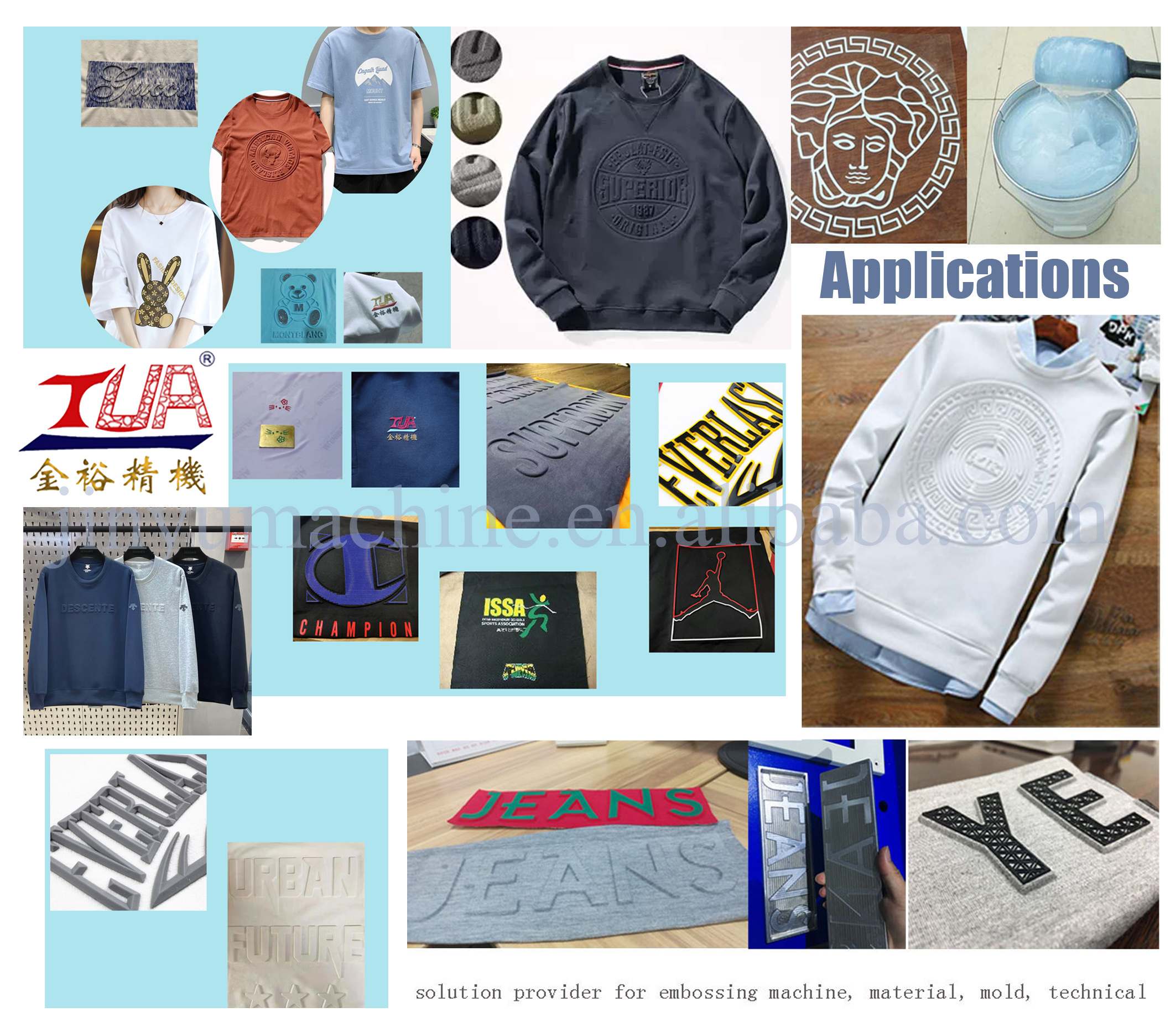

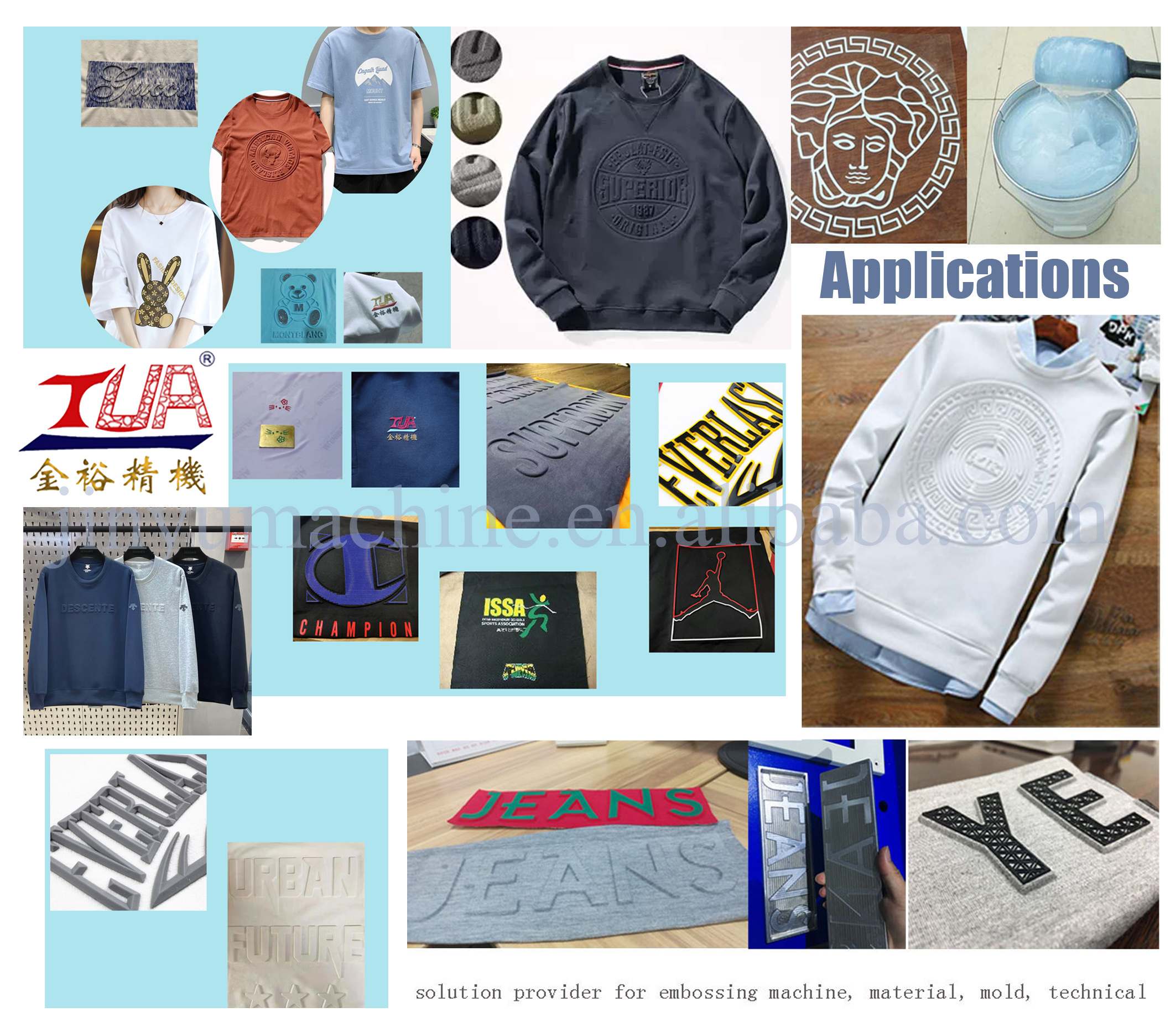

1. Application of embossing technology in clothing trademark logos

The general embossing process is printing, which is done by mechanical embossing after applying an appropriate amount of prepared ink on the printing plate. The printing surface completed by this method can only be flat and cannot produce a three-dimensional convex surface. Now, with our advanced technology and the use of new silicone materials, this process is called silicone concave and convex embossing process. It is to coat the printing plate with an appropriate amount of liquid silicone in a well-mixed color, and use a special embossing machine to emboss it at high temperature. The pattern formed on the trademark logo mold is heated and pressed. This method can produce a three-dimensional convex surface on various fabrics through the embossing process. It has a special 3D artistic effect, is high-grade and not easy to fall off, and is especially suitable for the clothing, luggage, and bag industries.

The embossing process is another derivative creation after the invention of printing technology in ancient China. It is a comprehensive process of printing technology and engraving art. Copper carving embossing and relief technology are the art of relief (flat carving) in printing technology. Without the development of printing technology and relief art, there would be no development of embossing.

The basic feature of relief art is that the pattern formed on a flat surface with a smaller area and smaller thickness should be:

1. The levels are clear, and the richer the expression, the better.

2. The three-dimensional image is concise and the expression is more rigorous and better.

3. The perspective is accurate and the more realistic the expression, the better.

The basic characteristics of the relief can be fully expressed through the embossing process. The main substrate for stamping and embossing is cloth. The thickness of embossed cloth is generally only a few millimeters to 10 millimeters. Various relief patterns need to be produced within this thickness range. The complexity can be imagined.

The embossing process is another derivative creation after the invention of printing technology in ancient China. It is a comprehensive process of printing technology and engraving art. Copper carving embossing and relief technology are the art of relief (flat carving) in printing technology. Without the development of printing technology and relief art, there would be no development of embossing.

The basic feature of relief art is that the pattern formed on a flat surface with a smaller area and smaller thickness should be:

1. The levels are clear, and the richer the expression, the better.

2. The three-dimensional image is concise and the expression is more rigorous and better.

3. The perspective is accurate and the more realistic the expression, the better.

The basic characteristics of the relief can be fully expressed through the embossing process. The main substrate for stamping and embossing is cloth. The thickness of embossed cloth is generally only a few millimeters to 10 millimeters. Various relief patterns need to be produced within this thickness range. The complexity can be imagined.

The embossing effect of embossing on the surface of clothing fabrics is as follows:

1. Create three-dimensional text and add decorative art effects.

2. Improve product quality and increase product added value.

3. High-grade fine bumps are difficult to counterfeit, and the anti-counterfeiting effect is considerable.

2. Promote the characteristics of the concave and convex embossing technology of Chinese clothing

China is the earliest country to use engraving copper plates. As early as more than a thousand years ago, engraved copper plates were used in the Song Dynasty. China is also one of the countries with the highest level of modern carving and embossing use.

The main features of Chinese embossing technology are as follows:

1. The composition design is scientific and reasonable. Fully consider the overall pattern structure and highlight the main part. Craft designers have a good foundation in plastic arts and can design good artistic effects.

2. Printing and concave and convex embossing processes are closely combined. The two complement each other. Printing creates good conditions for embossing. The embossing makes up for the lack of printing.

3. The carving process is exquisite and is created according to the principles of relief art. It emphasizes the perspective of different blocks and the intersection of the main levels. In the subtleties, the three-dimensional effect of the relief paper can also be considered.

The embossing effect of embossing on the surface of clothing fabrics is as follows:

1. Create three-dimensional text and add decorative art effects.

2. Improve product quality and increase product added value.

3. High-grade fine bumps are difficult to counterfeit, and the anti-counterfeiting effect is considerable.

2. Promote the characteristics of the concave and convex embossing technology of Chinese clothing

China is the earliest country to use engraving copper plates. As early as more than a thousand years ago, engraved copper plates were used in the Song Dynasty. China is also one of the countries with the highest level of modern carving and embossing use.

The main features of Chinese embossing technology are as follows:

1. The composition design is scientific and reasonable. Fully consider the overall pattern structure and highlight the main part. Craft designers have a good foundation in plastic arts and can design good artistic effects.

2. Printing and concave and convex embossing processes are closely combined. The two complement each other. Printing creates good conditions for embossing. The embossing makes up for the lack of printing.

3. The carving process is exquisite and is created according to the principles of relief art. It emphasizes the perspective of different blocks and the intersection of the main levels. In the subtleties, the three-dimensional effect of the relief paper can also be considered.

4. According to different products and paper characteristics, embossing printing and pressure adjustment are performed to make the convex layer rich and the texture strong.

Dongguan Jinyu Automation Equipment Co., Ltd are specialized in the development and manufacturing of PVC Machines, Silicone Machines, Silicone Garments Printing Machines, Silicone hydraulic machines , Silicone embossing machines, Silicone injection molding machines, PVC rubber patche machines, ect.

Ms. Bear

Ms. Bear